Engine Thermal Management

An engine cooling system must work to manage the thermal behaviour of the engine without allowing an individual part to overheat; if one part fails the whole engine will fail.

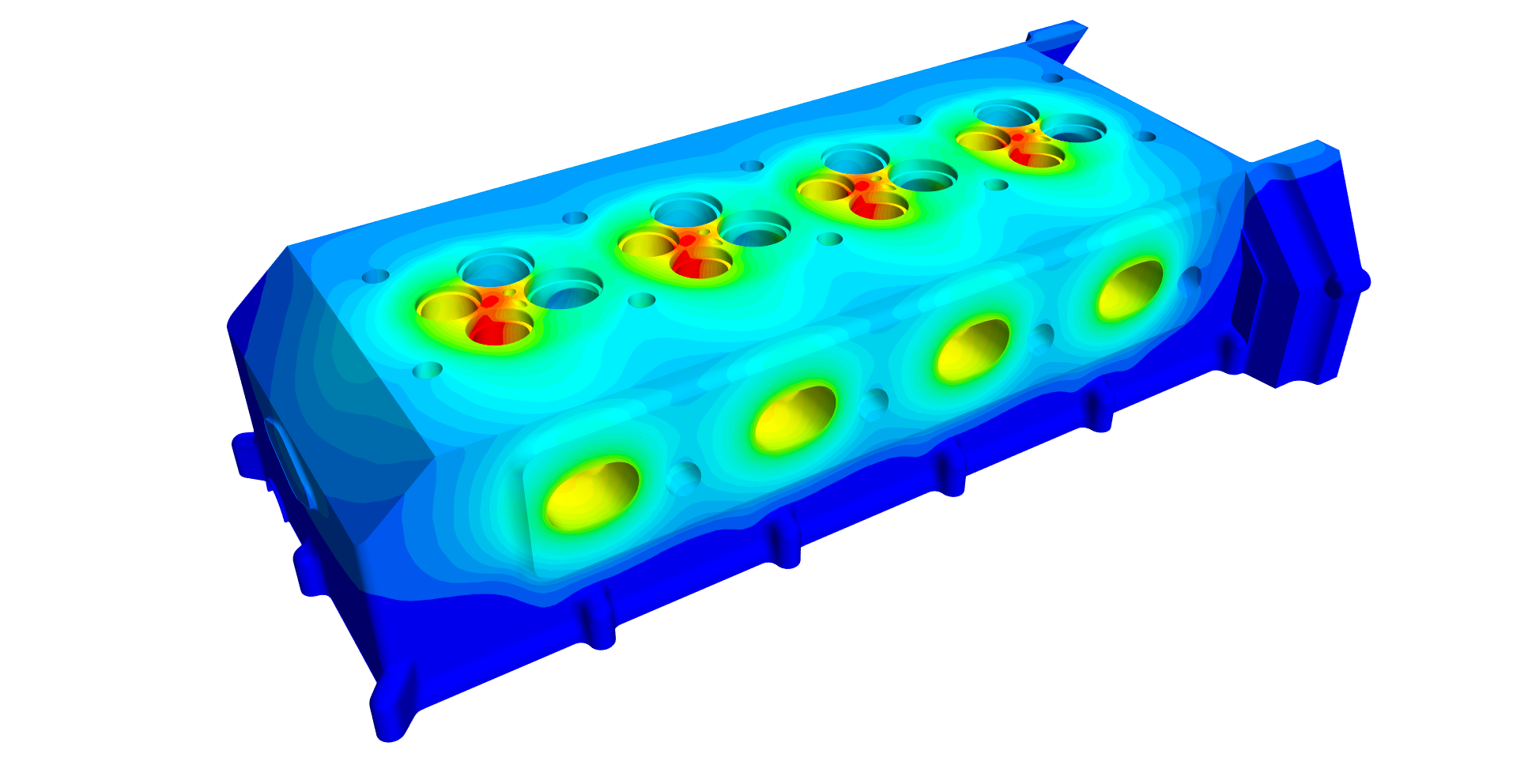

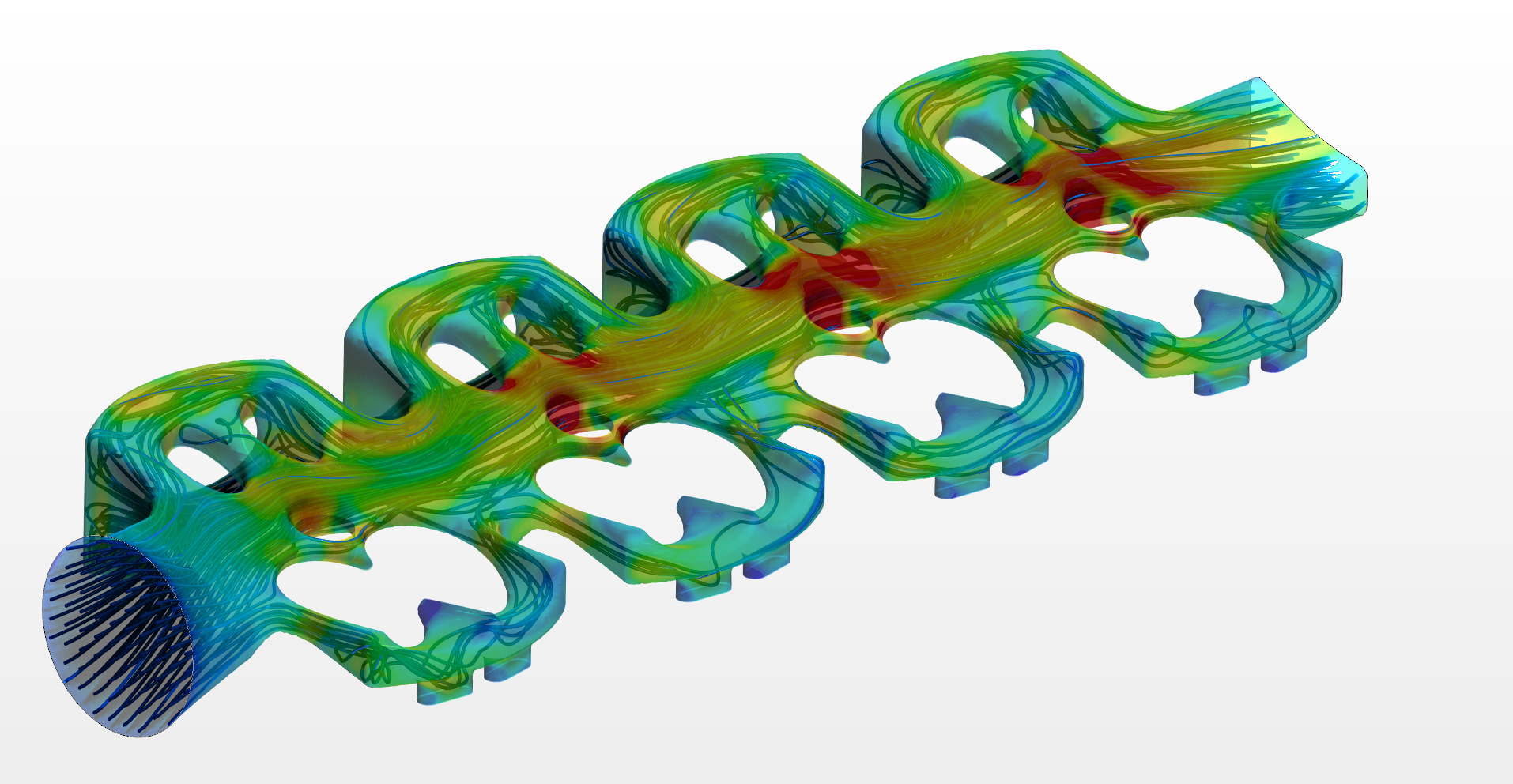

The engine is exposed to both high-cycle fatigue and low-cycle fatigue. High-cycle fatigue due to the normal engine combustion cycle and low-cycle fatigue due to the repetitive cycle of engine heat up, operate at high temperature and then cool down when the engine is switched off. Additionally, some regions of the engine are exposed to temperature hot spots and high temperature gradients, in particular the water jacket in the cylinder head above the dome.

It is therefore vital that the cooling system works effectively and efficiently.

Working with our Clients FTS Engineering Answers has built expertise of Engine thermal management, where we build conjugate heat transfer models, explicitly modelling the Cylinder head, valves, valve guides, valve seats, Engine Block, Pistons, Piston rings and their contacts, and the cooling jacket in both the head and the block. These provide in depth analysis and accurate insight of the temperature distribution throughout the engine. Subsequently, the thermal stress can be calculated and the design options evaluated, and with the application of different engine cycles both low and high cycle fatigue can be investigated providing insight into the reason for failures.

We are able to support our clients with a wide range of Heat Transfer activities, contact FTS Engineering Answers to discuss your questions!