Turbocharger Packaging

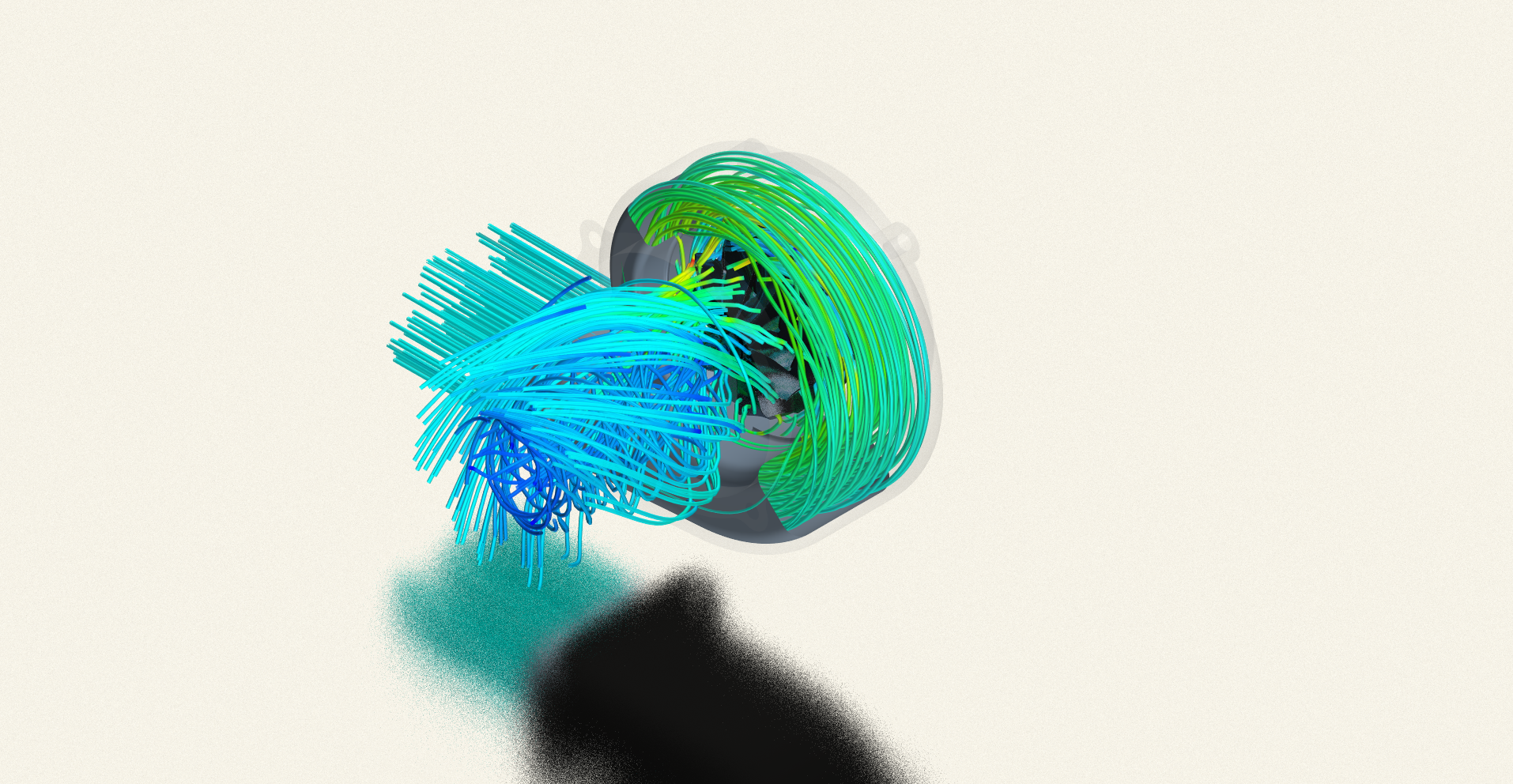

Turbocharger suppliers test their devices in idealized conditions i.e. straight inlets with no flow distortions. In reality, the real estate in an engine bay is limited at best which does not afford the luxury of ideal conditions. Subsequently, there is a need to know what effect this will have on performance.

FTS Engineering Answers has been working with OEMs to quantify these effects. Providing insight into not only the performance effects but improvements that can be made within the project scales.

In addition, FTS Engineering Answers continues to provide support on the following;

- By building detailed models of the compressor inlet, housing wheel and scroll, FTS Engineering Answers has investigated the cause of increased acoustics associated with different designs.

- Identified temperatures and thermal stress levels associated with the thermal heat up and cool down cycle to understand thermal fatigue issues of a twin turbocharger.

- Provided insight into the guide vanes of the turbine of a variable geometry turbocharger to understand potential hysteresis comparing the behaviour of the guide vanes as the open and close.

We are able to support our clients with a range of automotive packaging activities, contact FTS Engineering Answers to discuss your questions!